Biomass Fuel Energy Producer

ABOUT US:

BIO ENECO™ was established in 2011 with the mandate to produce renewable and sustainable biomass products. BIO ENECO™’s founder shared a common passion and goal to build a business that would emphasise on green technology. BIO ENECO™ aims to be a role model to reduce global dependency on traditional fossil fuels. Year by year, BIO ENECO™ solidified its foundation by building its departments, procuring supplies from various suppliers and obtaining certification of BIO ENECO™’s products.

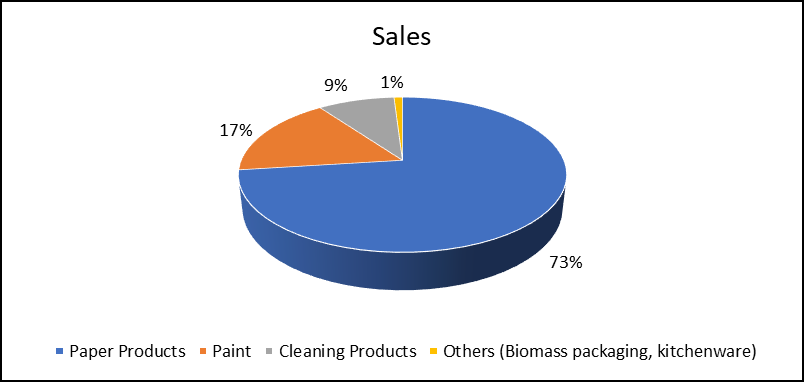

Over the decade, BIO ENECO™ has successfully positioned itself to be a major developer, manufacturer and supplier of premium grade biomass products in South East Asia. Considerable effort and resources have been put into the research and development of BIO ENECO™’s products. BIO ENECO™’s products meet the specifications of its customers from East Asia to European continent and are regularly sent to independent certification bodies for quality control and assurance, to ensure that BIO ENECO™’s products are viable for continuous exports. Moreover, BIO ENECO™ has a team to monitor the updates of global policies on carbon emission and environmental regulations.

OUR PRODUCTS:

Not all products are created equally. BIO ENECO™ takes pride and responsibility to source and produce the very best products to meet the most stringent quality that BIO ENECO™’s customers demand. BIO ENECO™ biomass products cater to different categories of boilers and furnaces, each with a specific requirement. Below is the list of the primary biomass products from BIO ENECO™:

Wood Pellets

As a leading and respected wood pellet manufacturer in Malaysia, we produce and supply wood pellet products of the highest grade. For your peace of mind, all our products have been independently inspected, tested and certified by SIRIM, The Standards, and Industrial Research Institute of Malaysia.

The high calorific values and other data in BIO ENECO™’s wood pellet have also been proven and certified using independent lab tests, carried out by the industries most renowned inspection and testing services, SGS.

Palm Kernel Shells

Palm kernel shell (PKS) in its raw, unprocessed form is readily applicable to boilers and furnaces. However, natural state, raw palm kernel shells contain high moisture and high level of unwanted contaminants such as germs, fungus, bacteria, diseases, insects, sludge, ammonia and etc., all resulting in bad odours, unclean emissions, and ultimately, low calorific values.

We can manufacture the PKS depending on our customers’ requirements. Next, we rotary dry roast the PKS to further kill any remaining bacteria. Our processing enhances the PKS burning qualities and cleans the biomass material to offer combustion that releases only clean, safe and aromatic emissions.

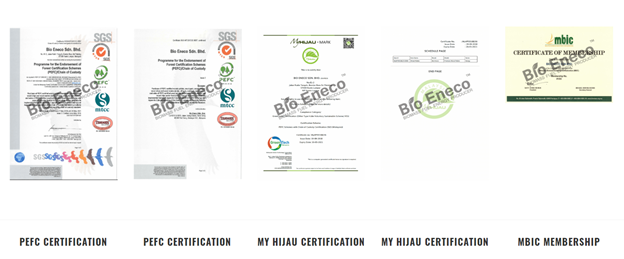

LICENSES & CERTIFICATES:

BIO ENECO™ is committed to adhering to the highest industry standards to instill confidence to its customers and stakeholders. Whether it is testing of BIO ENECO™’s products or compliance with international policies, BIO ENECO™ is dedicated to adopting the utmost procedures to fulfill its contracts. BIO ENECO™ plans for the future and executes in accordance with the law. BIO ENECO™ understands that long-term confidence can only be achieved with integrity and consistency.

Corporate social responsibility is highly prioritised in BIO ENECO™’s business and action plans. BIO ENECO™ collaborates with various government bodies, government linked organisations, professional associations and internationally recognized companies that provide inspection, verification, testing and certification services.

For more details about BIO ENECO™, kindly visit our website: www.bioeneco.com